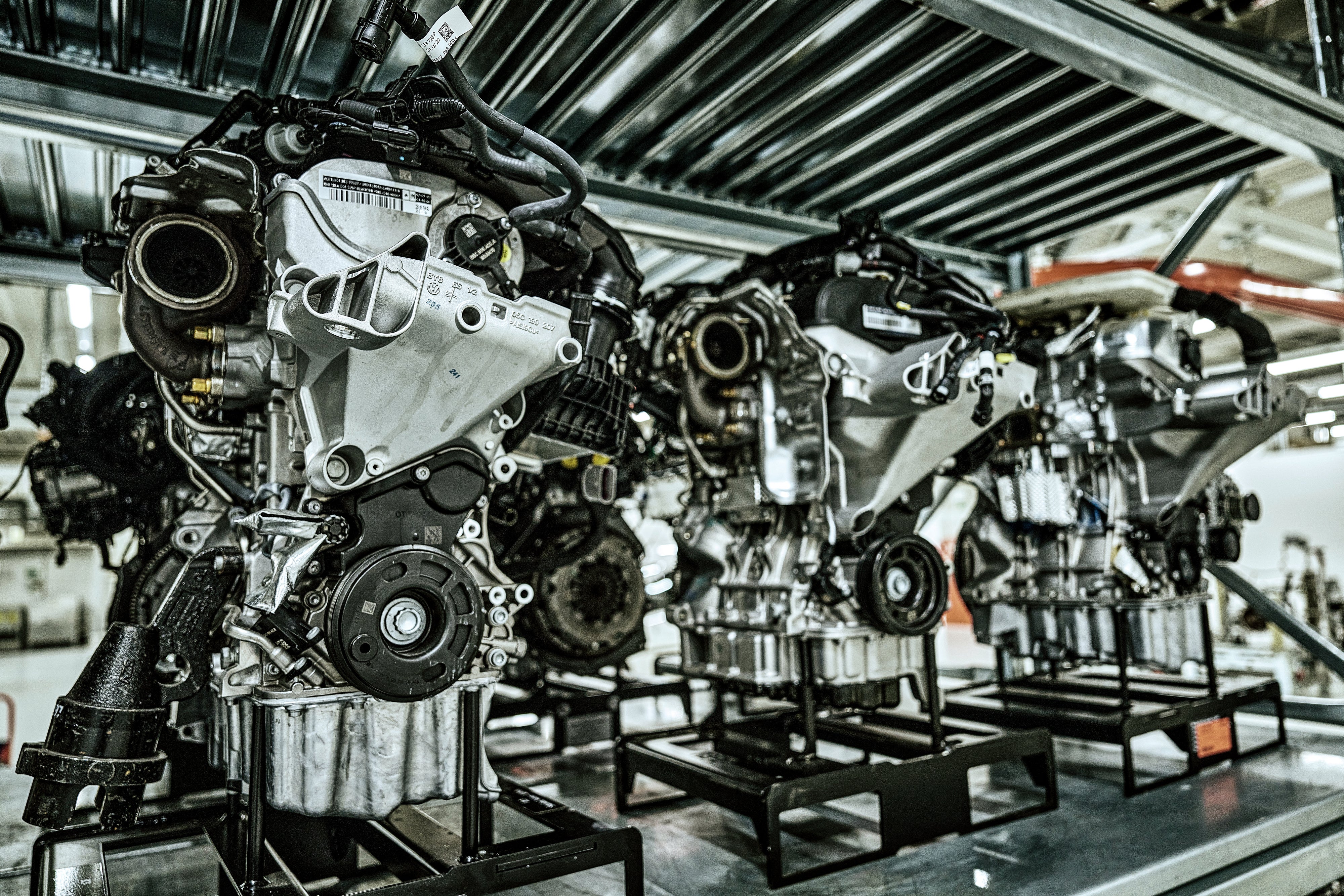

Take part in developing the EA 211 series engines and influence how millions of automobiles look across the globe. Cars bearing your mark will be driven in such places as South Africa, Latin America or India.

Overseeing the development of engines for fifty model series of vehicles and a total of seven brands from the Volkswagen Group? A great responsibility for Škoda Auto, but also a chance to prove that we are among the best in the field. Come join us as we give the world mobility.

The car manufacturer can’t do without experts to help it produce the highest quality drives and components. Are you experienced in technical development? Are you involved in project management, and can you coordinate a team? If so, the EA 211 project may interest you.

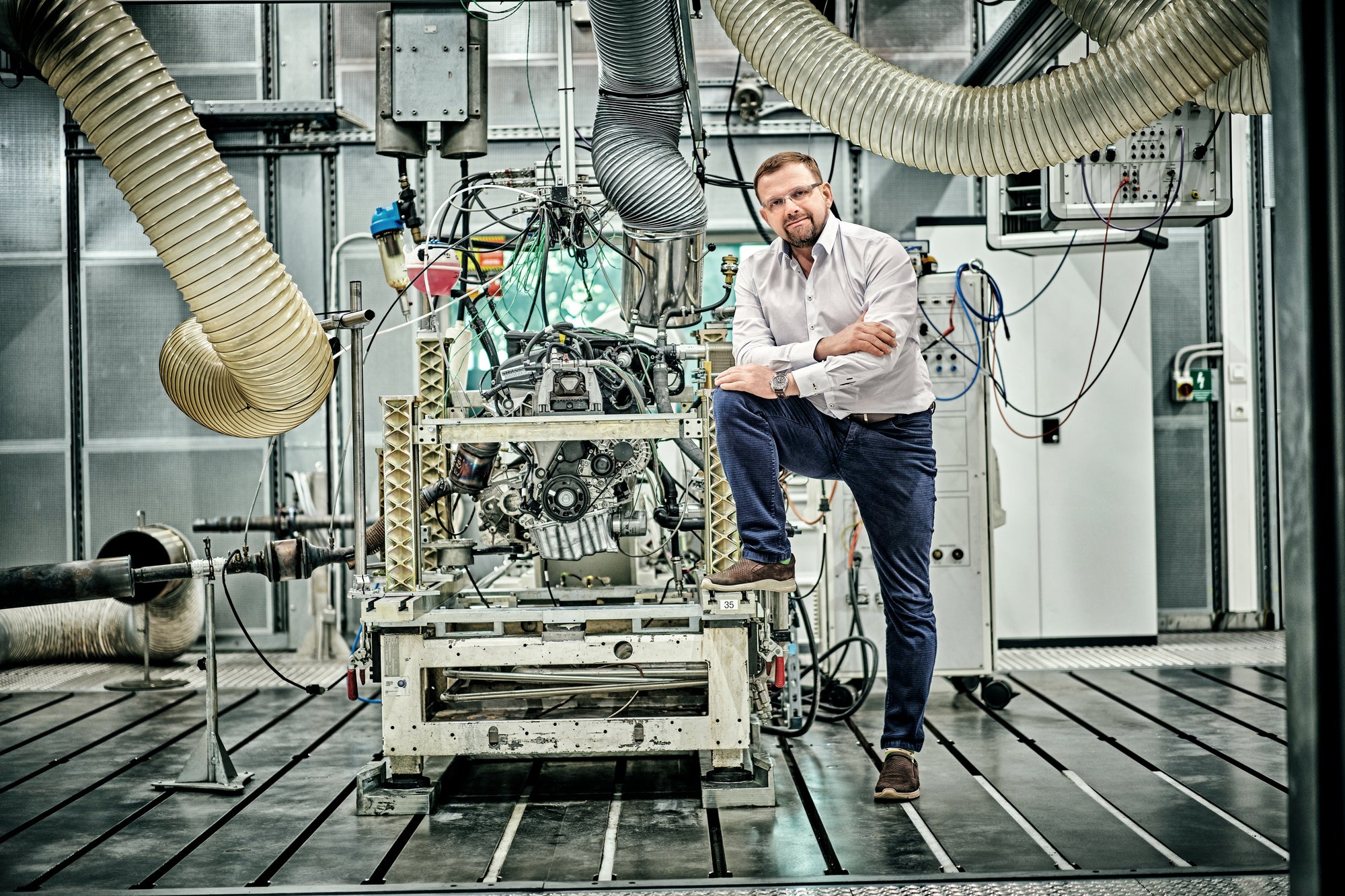

"You enter Mladá Boleslav, just a small town, but a whole world opens up to you. The automobile is among the most amazing products humankind has ever created. Taking part in its creation is fascinating."

Head of chassis and powertrain development

concern brands

model series

million vehicles

variants of powertrains

Whom are we seeking?

Help us develop everything that belongs to a quality engine. Durable gearboxes, high-quality gearing, the emission measurement system, shift modules and other components that vehicles cannot do without. Or help us coordinate individual tasks and get the result of our work out to the rest of the planet. With us, you will apply technical, communication and language skills, as well as a sense of organization.

What will EA 211 give you?

-

International reach

Look abroad to other group brands and learn from them.

-

Deep knowledge of the automobile.

You examine it right down to the last screw. Find out how the vehicle behaves in specific conditions. Test it in the cold, dusty conditions and extreme heat. In Mladá Boleslav and abroad. Get to know the new models first.

-

Valuable contacts.

Communicate with industry-leading suppliers.

-

Knowledge of global markets.

Each of them has its own specific legislative requirements to which the engine must be adapted. Create reports.

-

A team of experienced experts

The technical development of Mladá Boleslav has a rock-solid reputation worldwide. And you can be a part of it.

-

Knowledge of the latest technologies.

Elsewhere, you can hardly touch them. Keep one step ahead and be the first to learn new instruments and devices. Keep moving human knowledge forward.

-

Open a new chapter in engine development.

You will be part of it from the very beginning. Follow the tradition of Laurin and Klement and show the world what Czech engineers can do. Give the world mobility. Because movement is freedom.

The power unit 1.5 TSI evo2.

The latest generation of the world-famous petrol engine

Higher fuel savings – lower emissions. This is the combination on which the upgraded version prides itself. Initially, this modern four-cylinder engine will be available for 110 kW models. The Volkswagen T-Roc and T-Roc Convertible will be the first to receive it. It will also be introduced in other models by the end of 2023.

The main advantages of the drive include Active Cylinder Management ACTplus, an emission control module located near the engine. As well as the modern TSI-Evo combustion process. When developing the new generation of TSI engine, engineers also consider the future. The engine is compatible with renewable fuels and complies already with future emission standards.

World engine

Most of the world cannot do without internal combustion engines yet. The engines you develop in Mladá Boleslav will reach customers in Africa and India. See an overview of all the countries they're going to.

Which brands will the engines go to?

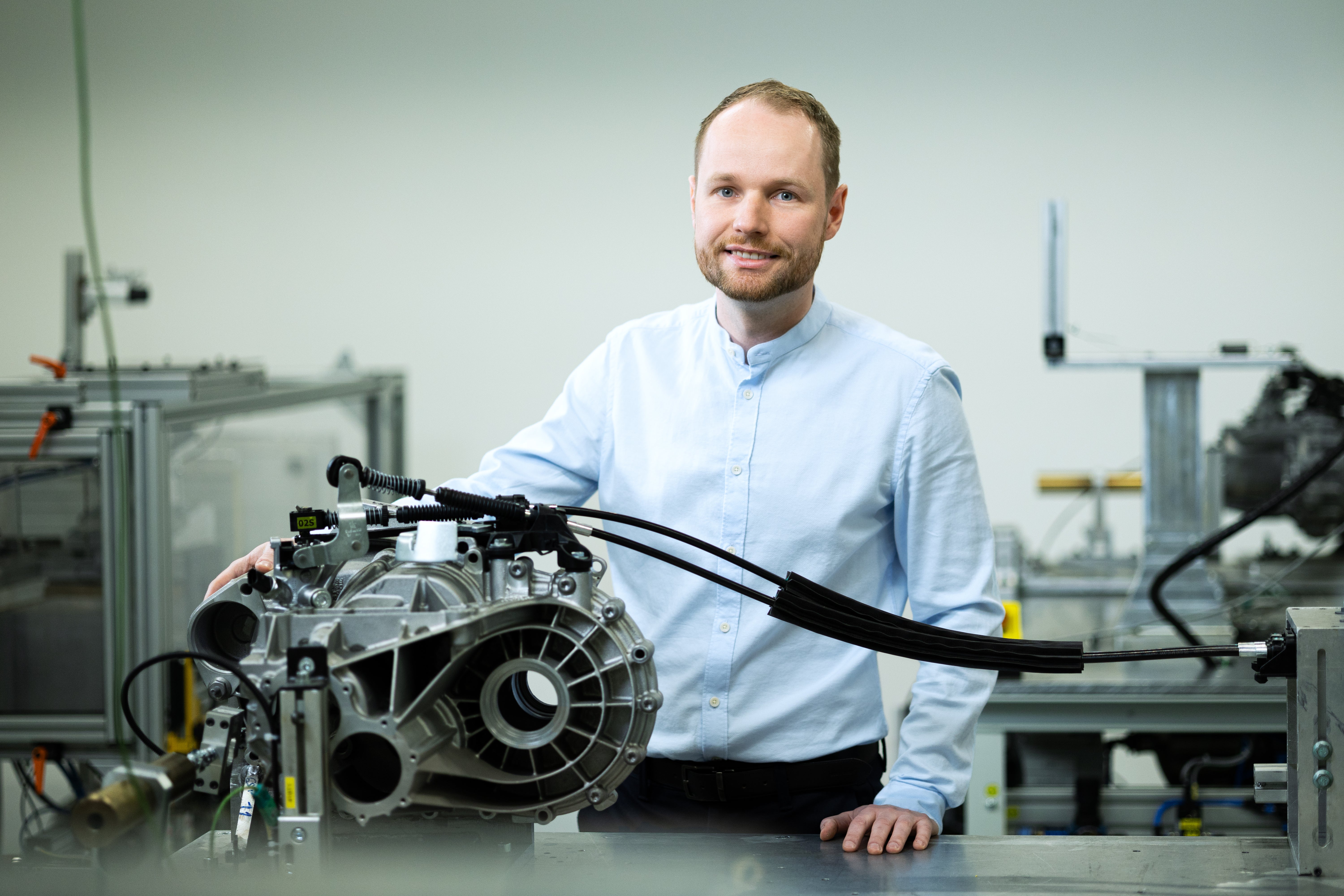

Jaroslav Prokop

Gear design development engineer

No car with an internal combustion engine would exist without a gearbox. Jaroslav Prokop is one of the leading Czech experts on gearing, an integral part of every transmission. Thanks to the EA 211 project, he will be working ever more frequently with other VW group brands. “Nowhere else in the Czech Republic are they being developed at the same level as in Mladá Boleslav.” What is local know-how?

What can you look forward to at Škoda Auto?

Interesting work that’s never boring and a decent salary. That sounds good. But what makes it even better are our benefits! See what awaits you.

"With us, you can choose how much you want to dive into the technical side of engines. You solve everything yourself in detail, or turn to reliable, experienced designers."

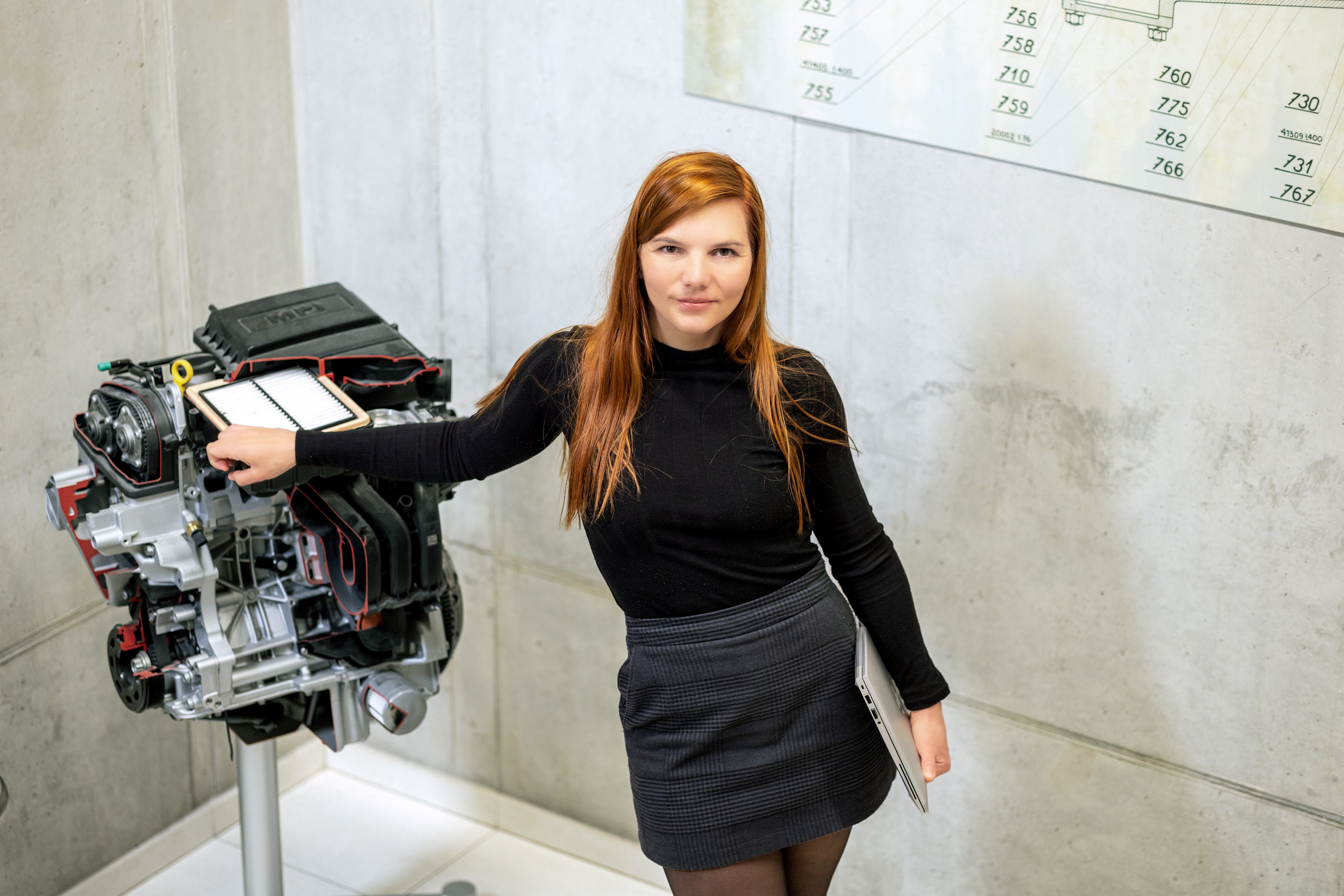

Technical Project Management India

"In technical development, you touch the automobile right from the start and influence future events."

External manual gear shift designer

Technology at your service

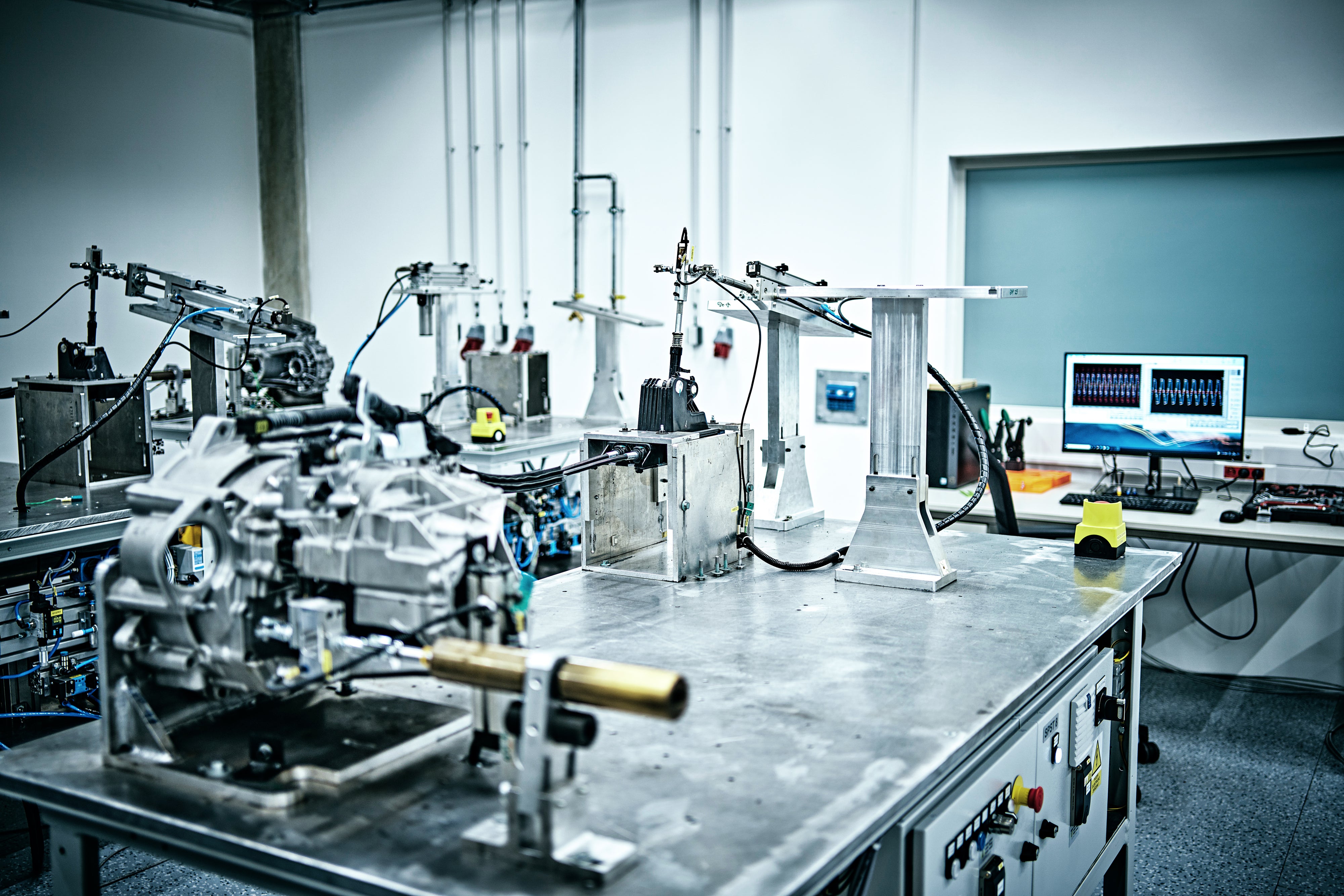

The most advanced technology and equipment. In the Engine Testing Center, you will get to work with machines and procedures exclusive to just a few companies. Here are some examples:

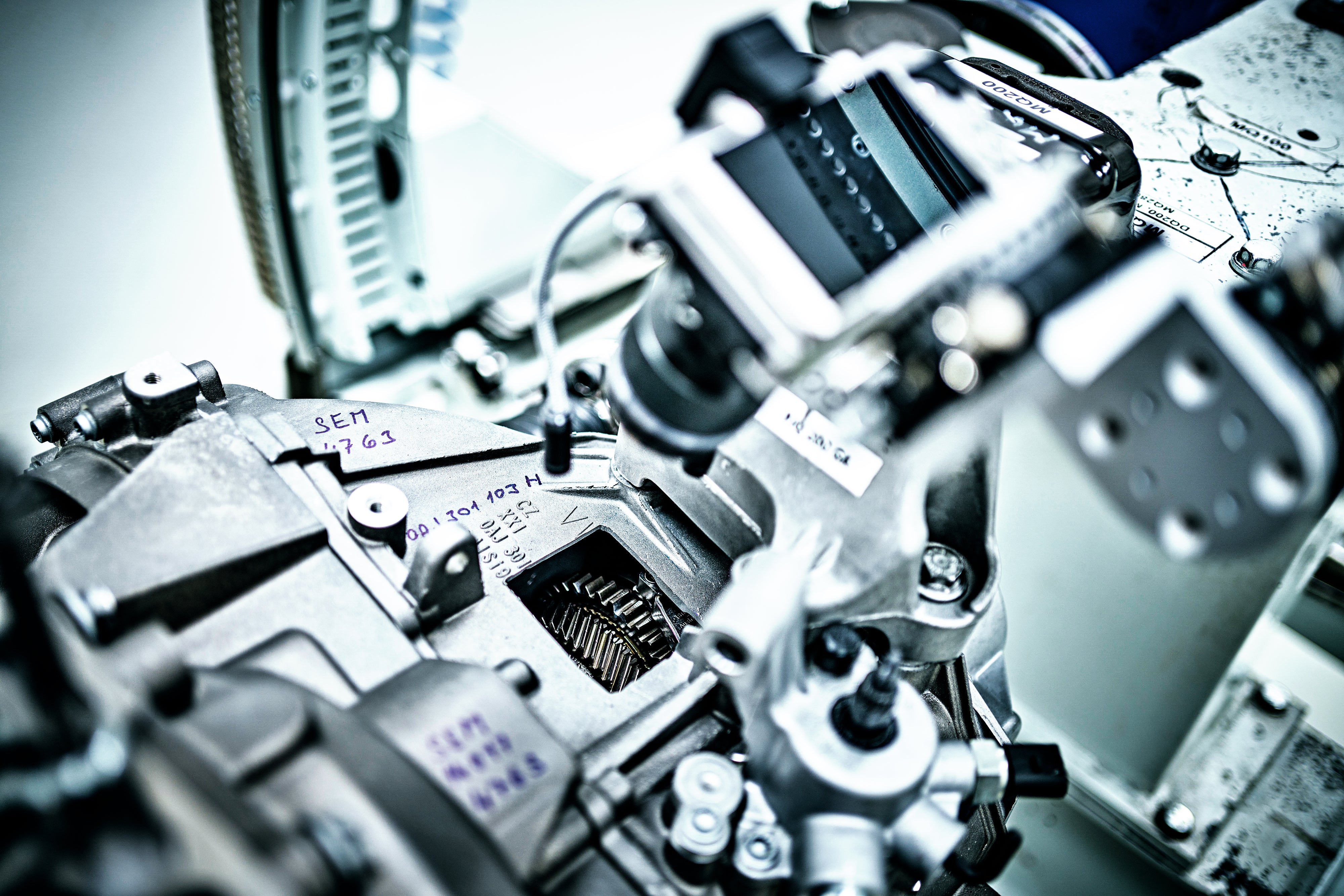

Test stand of the gearbox to determine the engagement marks of the gearing

It has undergone five development stages since 2008. The testing considers the complete deformation of the gearbox, including the engine block, the rigidity of which also affects deformation of the clutch housing. To best simulate real operating conditions, the tested powertrain is anchored onto beds – just like in a real vehicle.

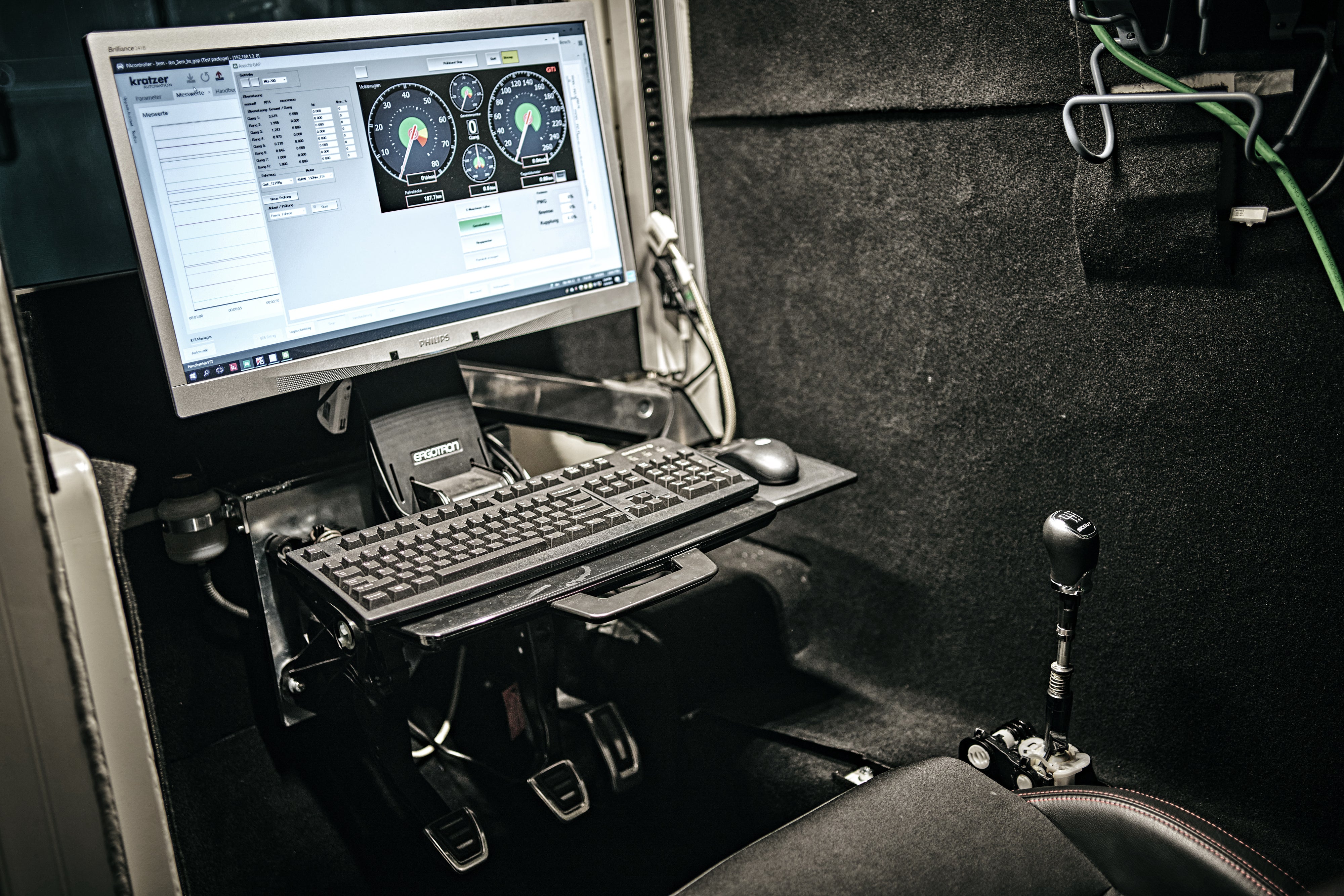

Test stand of gearboxes with acoustic cabin

The unique acoustic cabin allows durability and functional tests of gearboxes. These are controlled automatically. The cabin perfectly simulates the driving conditions. It considers both control and perceived noises. It decreases development costs and effectively reduces the testing time of the given gearbox.

External shifting test stand

In the Engine Testing Center, you will find a total of five test states of external shifting. They run based on the MQB and PQ platform for passenger vehicles. One test lasts three to four weeks and attempts to mimic real traffic as much as possible. Therefore, the shift tracks and gearbox installation are identical to those in the car. Simulation of hand shifting is performed using a pneumatic actuator.

Engine test stand

It can reproduce any operating mode of the tested engine – starts, driving on a highway as well as uphill or downhill driving. It allows us to select the desired type of fuel and precisely measure its consumption. There is also emission technology that analyzes exhaust gases. Thanks to the automation of the control system, the test station can operate almost 24 hours a day.

Jiří Borovička

Project coordinator of gearbox test stands

What is the main task of specialists who develop gearboxes? To ensure functional, quiet and reliable vehicle propulsion. "Customers should not even know they have such a device in the car," describes Jiří Borovička, project coordinator for gearbox test statuses. Read the entire interview or listen to a report from his workshop.

Have a look at the experts at hand

This is what a day at the Engine Testing Center looks like. Meet the people here and see how the local specialists approach their work. Will you find your own desk here?